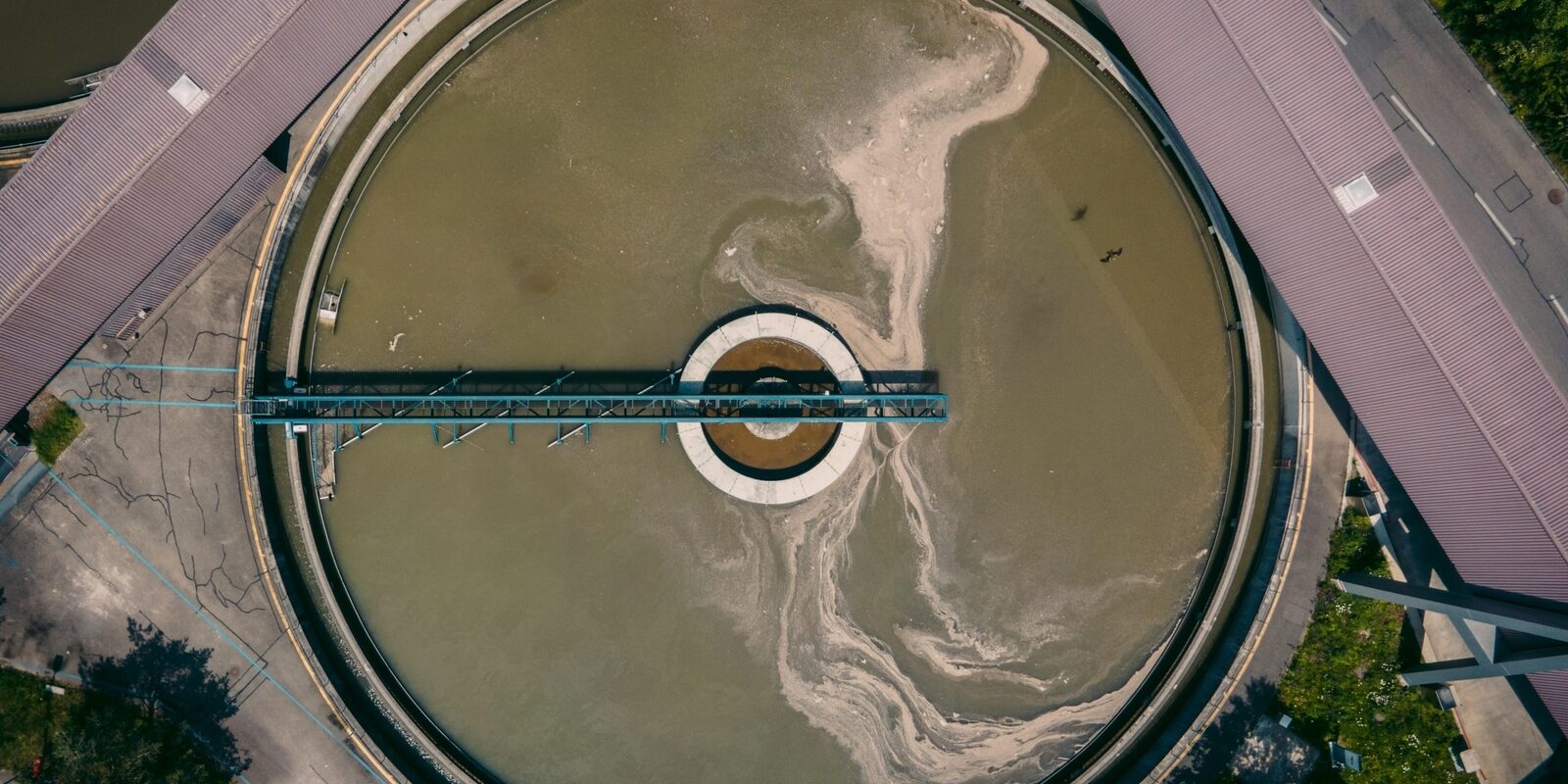

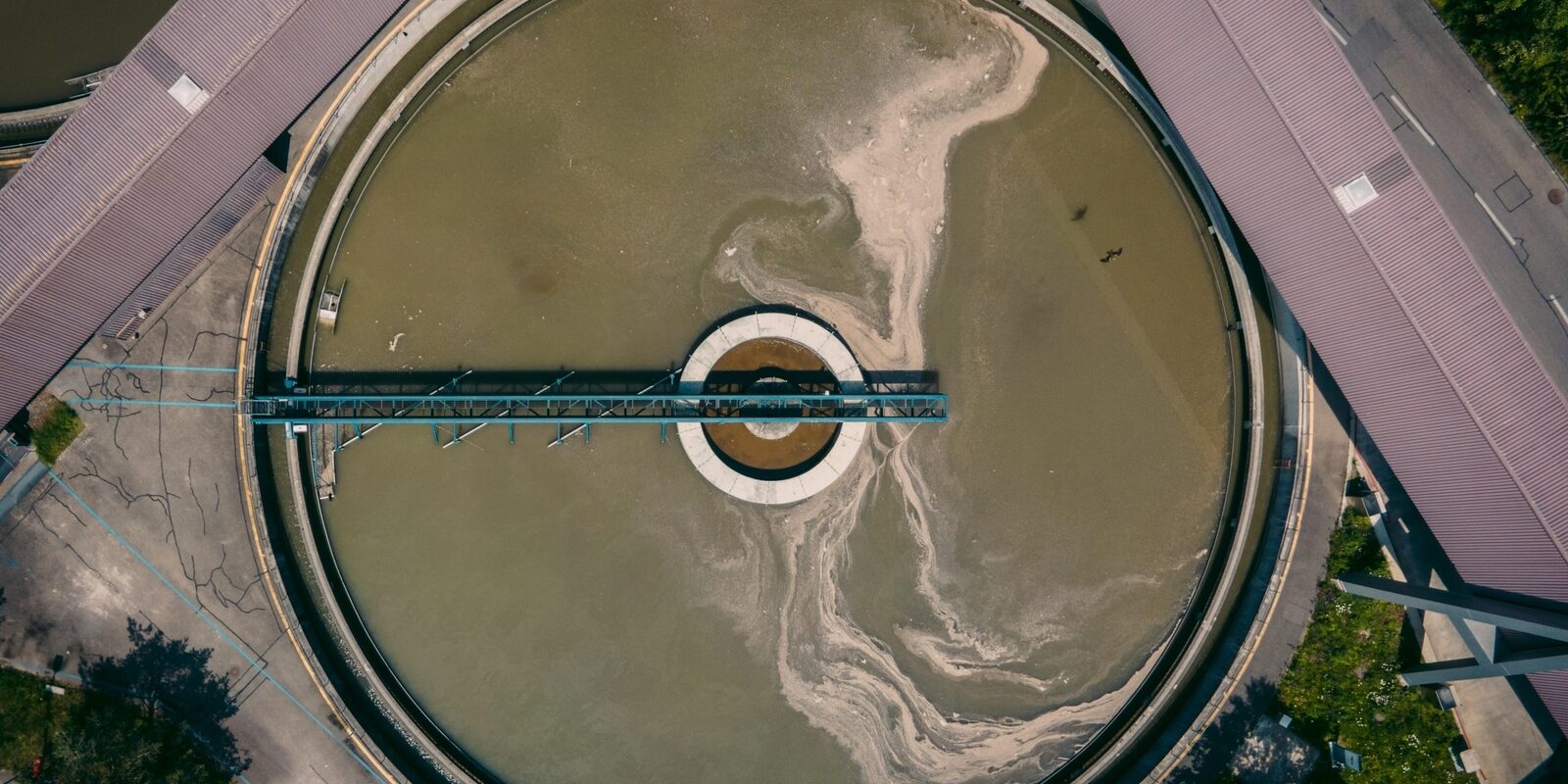

When it comes to sewage treatment, choosing the right pump is a critical decision that will impact the effectiveness of your entire operation.

The two main types of pumps commonly used for sewage treatment are submersible pumps and centrifugal pumps, which is what we specialise in here at Hydromarque. While both types have their benefits, choosing the best pump for your specific needs requires a thorough understanding of how they differ from each other.

We will guide you through the two most common types of pump used in sewage treatment plants, focusing on their individual advantages and disadvantages so you have a clearer picture of what makes for the best solution for your plant. Whether you are looking to upgrade your existing pump or put in place an entirely new sewage treatment system, this guide will provide valuable insights to help you make an informed decision.

Submersible pumps are noted for being able to operate completely submerged in water. In fact, this is the only way in which they can operate, as the water cools the motor inside during operation. Its submarine quality is possible through the very design of the pump, as the motor is sealed watertight to the body of the pump.

Best suited for light industrial applications, a submersible pump pushes water to the surface by converting rotary energy into kinetic energy, then into pressure energy. These pumps are designed predominately for handling liquids, but some can handle solids.

Its major advantage over other pumps is that it never has to be primed by removing air, as it is already engulfed in liquid. The quiet efficiency of these pumps, which is enhanced by not having to create water pressure to move water, is also a plus point.

At Hydromarque, we supply submersible pumps that are strong enough to handle both solids and liquids and with the elite durability of Gorman-Rupp’s engineering, our pumps can last up to a decade before needing servicing.

Conversely, dry-operation centrifugal pumps are the most common pumps used in sewage treatment plants. They operate either underground or on the surface, and use centrifugal force to pump wastewater - as it enters the pump, it revolves around at incredibly high speeds via an impeller and then moves to the edge by the principles of centrifugal force.

The reason centrifugal pumps are such a popular pump for sewage treatment plants is that they are space-efficient, easy to install and don't clog up as much as other pump types. If there are no troubles with the impeller, these pumps are built to last for years before being affected.

One major put-off of most centrifugal pumps is that they require priming now and then. But at Hydromarque, the pumps supplied are self-priming, going through a process of creating a partial vacuum to evacuate any air from the pump.

Models such as the Gorman-Rupp Super T Series have been installed by us and greatly satisfied customers that include Anglian Water plumbing and numerous food processing plants. Hydromarque’s line of submersible and self-priming centrifugal sewage treatment pumps will be a major boost to your efficiency.

Plus, our exceptional customer support makes us a crowd-favourite option up and down the UK, so if you are looking for new pumping solutions and installation services, look no further. Explore our pumping application categories to learn more about our products and services, or contact us to find out what the UK’s best pumping solutions team can do for you.

Get in touch

Get in touch with one of our technical experts today who would be happy to assist you.

© 2026 - Hydromarque. All rights reserved.