There are all kinds of different types of pump out there, from positive displacement designs to submersible pumps and plenty more besides. Choosing the right type of pump for your specific application can be challenging, particularly if you’re not familiar with the pros and cons of each design.

That’s where we come in. As the UK’s leading provider of pumping solutions, we know the industry and its current offerings inside out. Today, we’re sharing some of that knowledge with you, shining the spotlight on self-priming centrifugal pumps.

This is the most popular type of pump we offer here at Hydromarque, and for good reason. But before we delve deeper into the advantages of this design, let’s first take a look at what a self-priming pump is and how it works.

Pumps are designed to move liquid from one place to another. So, if air gets into the system, the pump can no longer do its job. Air locks typically occur in situations where the pump is installed above the liquid. If it’s not fully submerged, it can draw in air instead of fluid, which can lead to it overheating and sustaining damage.

There are a number of different solutions out there for this problem, including non-return valves and even secondary pumps - but all of these solutions are complex, expensive and require additional maintenance. Not ideal.

This is where self-priming pumps come into their own. They’re able to detect air in the system on startup and remove it without the need for additional equipment, reducing complexity and keeping costs down.

Some pump designs are inherently self-priming, like positive displacement pumps. However, their ability to remove air from the suction line depends very much on the condition of the pump; worn out seals can limit how much air is removed from the system, for instance, compromising the pump’s efficiency. Plus, positive displacement pumps aren’t designed to be run dry. If too much air collects in the suction line, the pump may overheat and fail prematurely.

By contrast, centrifugal pumps aren’t naturally self-priming, as the suction and discharge parts of the pump aren’t sealed off from each other. This means that air can easily pass into the suction line. In response to this problem, manufacturers like Gorman-Rupp have worked on creating self-priming centrifugal pumps - a design that has taken the industry by storm.

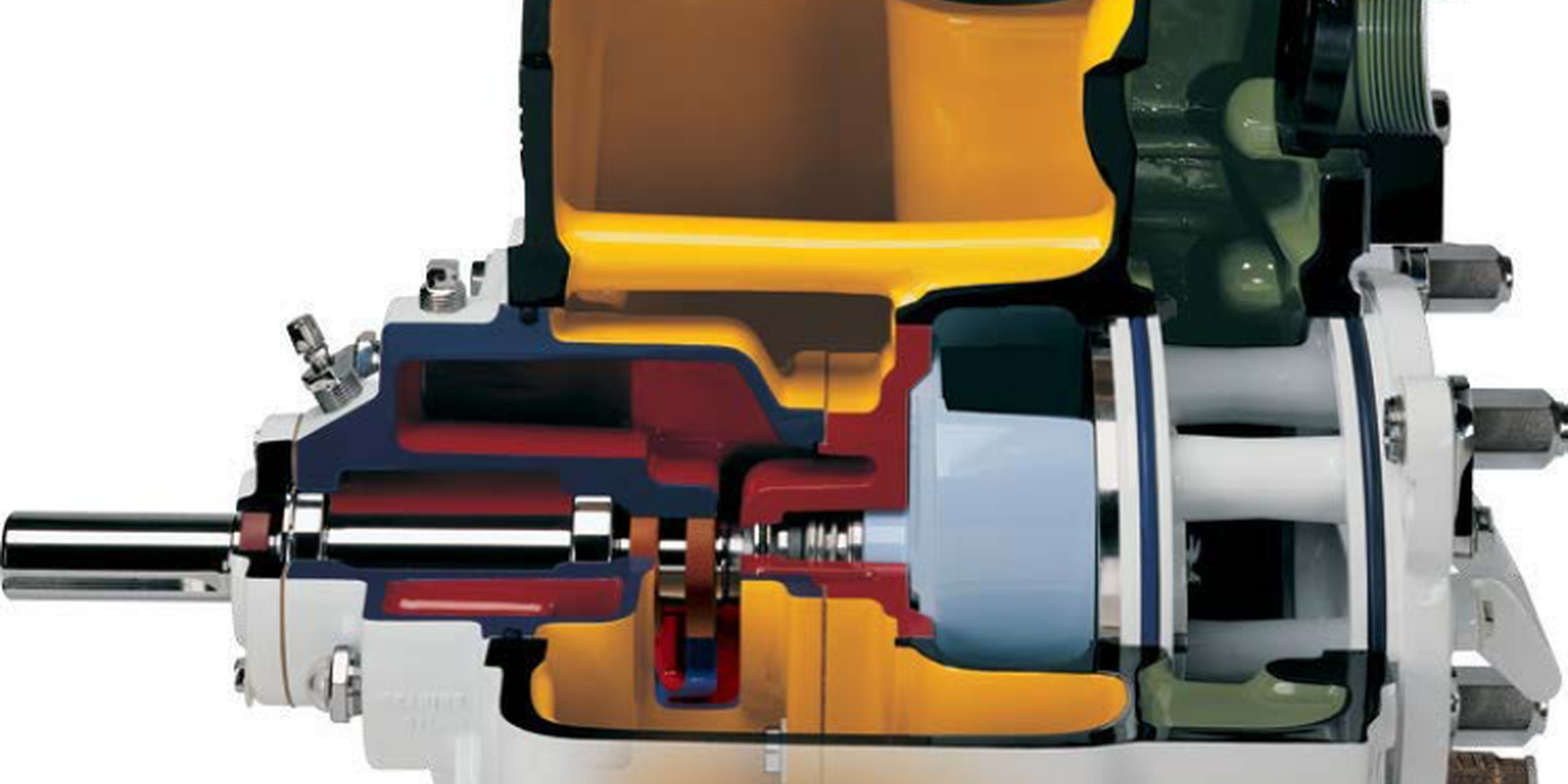

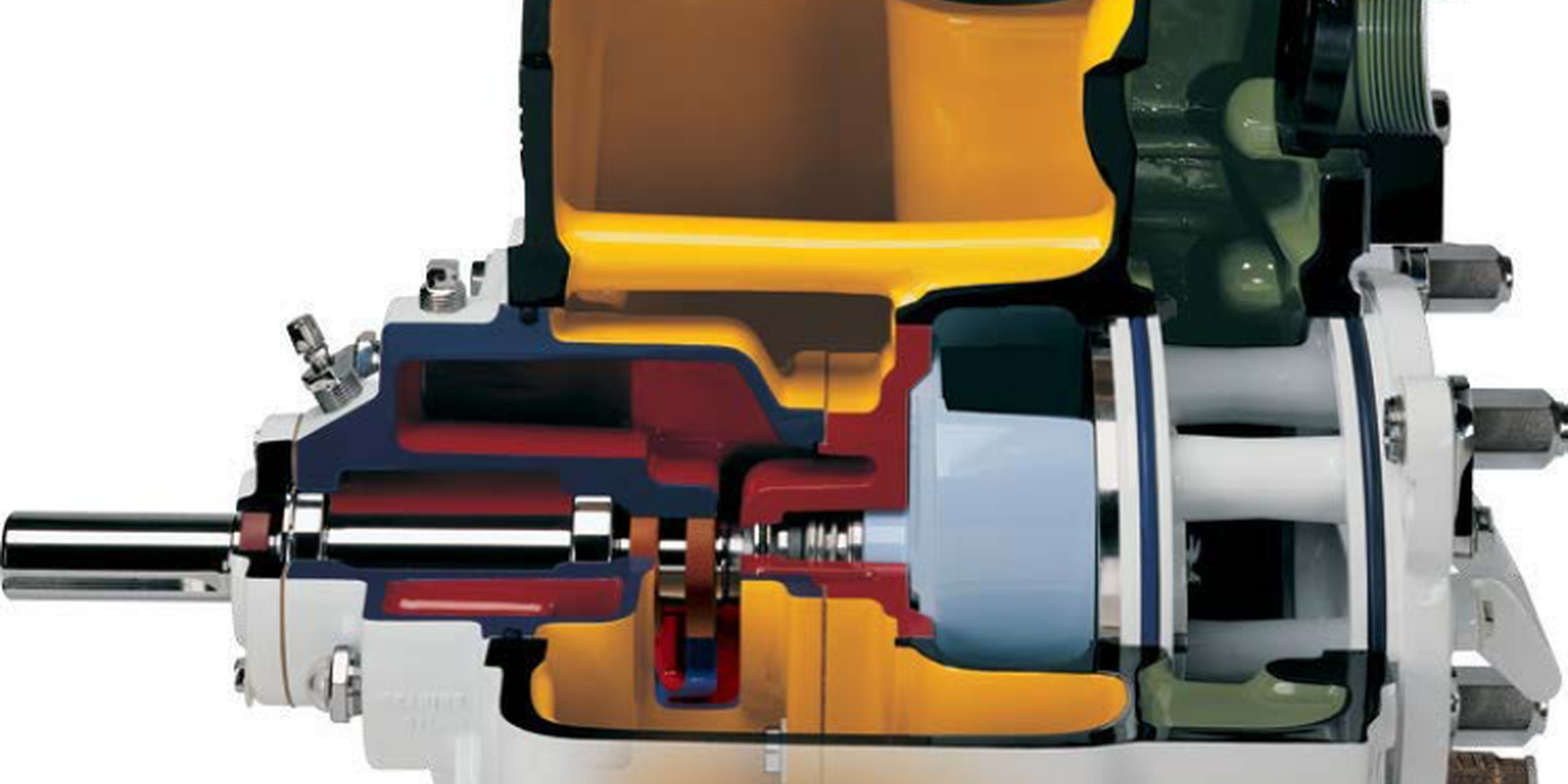

Significant alterations were made to the original centrifugal pump design to create the self-priming versions we know today.

The impeller and volute casing is housed in a separate reservoir containing enough liquid for the pump to begin running, even if there’s air in its suction line. Once the pump is up and running, it’s able to use the liquid in its reservoir to create a vacuum, removing air from the suction line and allowing normal operation to resume.

It’s imperative that the fluid reservoir is topped up when the pump is installed and each time it’s serviced; without this supplementary fluid, the self-priming element of the pump simply won’t work. This will allow it to run dry, eventually causing it to overheat and fail.

Although self-priming pumps are now the default choice for many applications, they do have their limitations - all of which can be overcome with regular inspections and maintenance. Common problems can include:

The configuration of the pump’s suction pipework should be carefully considered, too. If it’s excessively long, the pump will need to prime for much longer to remove all of the air in the system. If it’s unable to prime before the liquid in its reservoir is depleted, the pump will run dry, causing damage and premature failure.

Servicing and ongoing maintenance is equally critical, as it helps to minimise wear and maintain the efficiency of the pump. The less efficient a pump is, the harder it has to work - and the more likely it is to fail. Checking the impeller regularly and removing debris will make a significant difference to the lifespan of the pump.

Hydromarque is the UK’s leading supplier and installer of self-priming centrifugal pumps. Our range of Gorman-Rupp pumps lead the way in terms of efficiency and durability, and our experienced team of engineers have the know-how to help you get the most out of them.

From designing and commissioning complete pumping systems to carrying out servicing and ongoing maintenance, we do it all here at Hydromarque. Want to learn more about how we could help you? Get in touch with us today.

Pumps that will last. With surface mounted pumps, there's less downtime, fewer breakdowns, and lower maintenance costs.

Expert advice. We know pumps inside and out.

Seamless integration. Our pumps fit into your system with ease.

Reliable support. We're trusted by customers nationwide.

We’ll help you find the right solution for your pump application. Our pumps are more efficient, more cost-effective, and hassle-free.

Get in touch

Get in touch with one of our technical experts today who would be happy to assist you.

© 2026 - Hydromarque. All rights reserved.